|

Specialized in metal forming.

Nedschroef Machinery is a leading manufacturer of cold and warm metal forming machines.

Their high-performance machines allow mass production of fasteners and parts.

Nedschroef's goal is to provide the highest quality equipment and solutions to improve our customer’s performance.

|

Headers

- Nedbase: Compact, high-speed machine with an excellent price-quality ratio

- Nedform: Machine with modular design, client-specific expansion options, hi-tech components and demand-oriented automation solutions.

- Nedform Hybrid: New forming capabilities and high productivity

- Nedmax: Machine for large-diameter parts.

- NC714: Makes forming easier and efficient

|

Boltmakers

- Nedbase Boltmaker: economic machine producing bolts in one operation.

- Nedform Boltmaker: producing bolts in one operation.

|

|

|

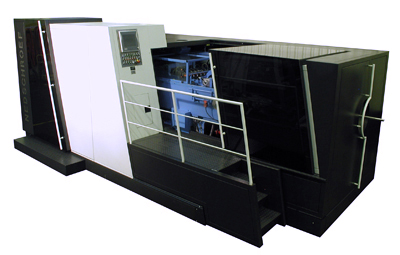

| Nedbase Boltmaker |

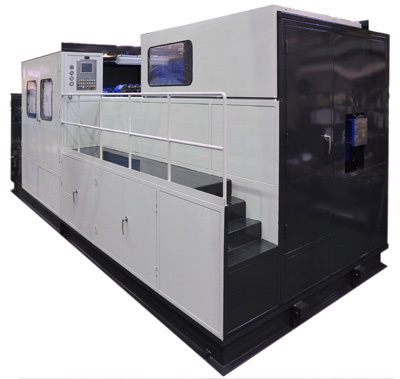

Nedform Boltmaker |

|

The Nedbase cold forming machine is extended

with an integrated pointing and threading station to form bolts in one operation.

The dynamic bolt making process ensures a high-quality output at high speed. This economic machine with high-quality components requires

a relatively low investment. |

The Nedform cold forming machine is extended with an integrated pointing and threading station to form

bolts (M5 to M24) in one operation. The dynamic

bolt making process ensures a high-quality output

at high speed. The unique modular concept enables

customers to choose exactly the right features that

are needed to fulfil their specific requirements. |

Benefits

- Minimum floor space required because of

compact design and one-cell-operation

- Consistent product output and long lifetime of tooing.

- High productivity

- Operator friendly and easy maintenance

- Product versatility: suitable for an extensive wide

range of bolts or parts

|

Benefits

- Minimum floor space required because of

compact design and one-cell-operation

- Consistent high-quality product output and long lifetime of tooling.

- Operator friendly and easy maintenance

- Product versatility: suitable for an extensive wide range of bolts or parts

- Modular concept

|

|

|

Hot Nut Former MW

High productivity and cost-efficiency

This high capacity hot nut former is suitable for forming nuts from M14 up to M42 with a maximum width across flats of 33 to 65 mm.

The hot nut former requires a low investment and is designed for a very cost efficient production of all kind of nuts.

Benefits

- Durable design

- Short set-up times

- Consistent product output and long lifetime of tooling

- Compact design

- High capacity and high productivity

- Operator friendly and easy maintenance

|

Straightening Machine RRA

High productivity and cost-efficiency

Straightening machine RRA straightens axially symmetric parts like long axles, shafts, bolts, screws and rods. Straightening improvement is up to factor 10.

The machine is suitable for the following product shapes: with or without thread, with flange in the middle, with stepped shafts and with threaded ends.

Benefits

- High output

- Short set-up times

- Fault signalization: automatic rejection of defect parts

- Easy reproducibility of proven settings

- Compact design

- Operator friendly and easy maintenance

|

Nedshear

High-speed impact cutting

The Nedshear high-speed impact cutting machine produces blanks from coiled wire.

The high-precision linear wire feeding system with servo direct drive makes this machine very accurate.

Benefits

- Accurate cut-off length

- High shearing speed

- Fully automatic

- Length corrections possible during running

|